This article explains how effective Purchasing Management secures resources, controls costs, and drives operational efficiency for small and medium-sized businesses (SMEs). Discover the key processes, challenges, and benefits of using an advanced cloud accounting system like Qoyod to optimize your procurement function. |

No organization can succeed without effective Purchasing Management, which is responsible for securing the necessary resources and supplies for production and operation, ensuring the budget is spent wisely. It also guarantees that the company obtains high-quality goods and services at the lowest possible cost. In this article from Qoyod, we explore the concept of Purchasing Management and its critical importance in improving the financial and operational performance of organizations globally.

Defining Purchasing Management

Purchasing Management is the function dedicated to securing the resources and services that enable an organization to execute its operational and production processes optimally. Its role is not limited to simply buying supplies; it also includes inventory monitoring, supplier selection, and quality control to ensure the best possible value for money invested.

The responsibilities of Purchasing Management extend to continuous inventory monitoring, timely replenishment before stockouts, and selecting the best suppliers based on price and quality. Furthermore, it works to foster strategic relationships with vendors to reduce expenses and achieve the maximum possible return for the organization.

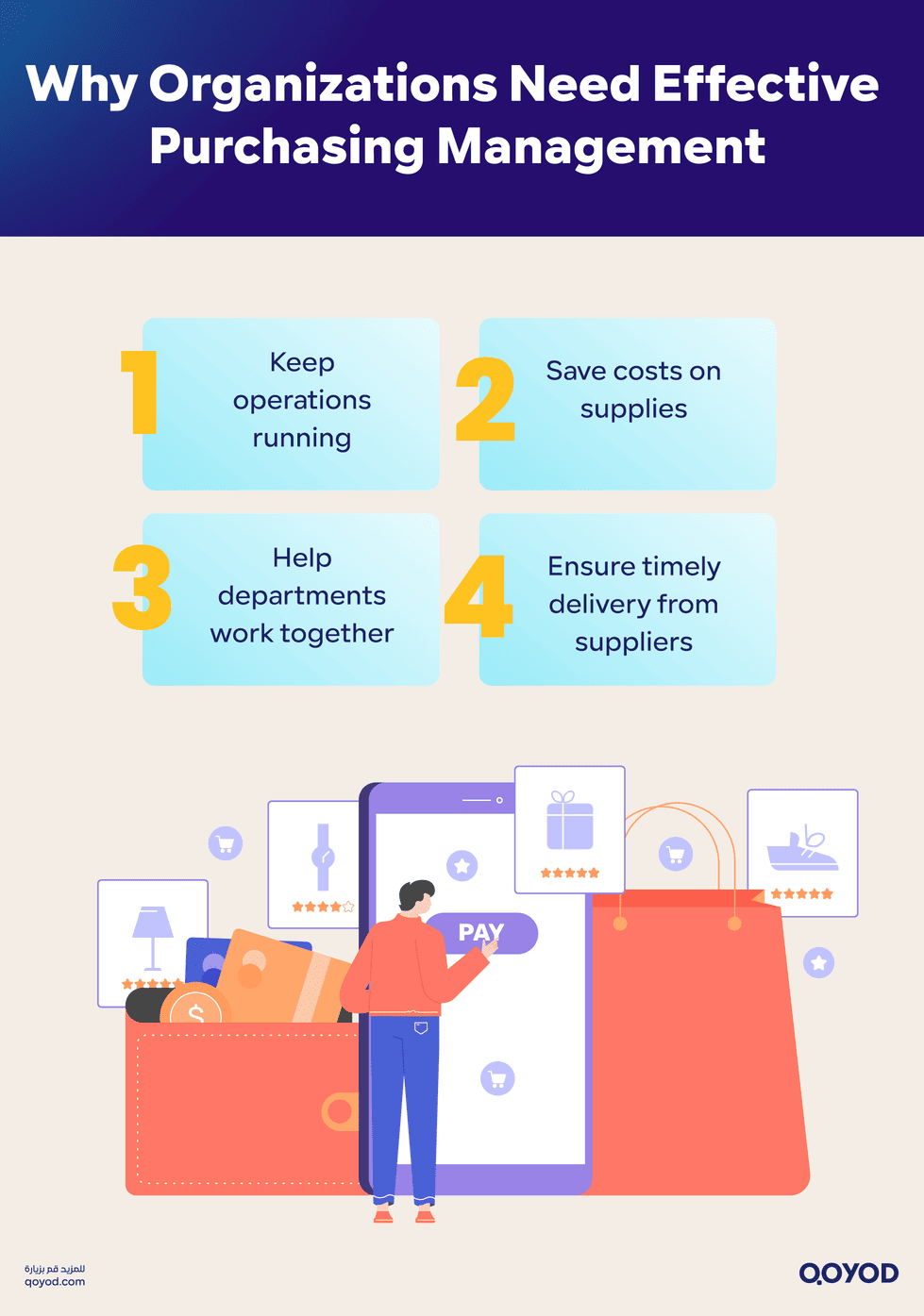

Why Organizations Need Effective Purchasing Management

The absence of a dedicated Purchasing Management function leads to disruptions in production processes and increased costs. Therefore, this function is a fundamental pillar for ensuring business continuity. The most prominent reasons for its importance include supporting the organization’s operational plan, lowering expenses by procuring the most suitable supplies, and facilitating cross-departmental collaboration to achieve operational efficiency.

- The role played by Purchasing Management is what ensures the organization’s operational plan proceeds as intended.

- It contributes to cost savings by selecting the best-quality goods at a reasonable price, and it provides suppliers with the specifications needed to deliver supplies on time.

- It works on coordinating between multiple departments to achieve collaboration and joint work, leading to the best possible outcome.

Procurement specialists are characterized by strong negotiation skills that help them secure the best deals. They also rely on market data and periodic reports to anticipate price changes and make appropriate purchasing decisions. A number of these decisions directly impact the company’s profitability and operational efficiency.

- Based on the information available to Purchasing Management, it becomes easier to make correct decisions regarding the goods required for purchase and the sourcing channels.

- Understanding the laws governing the sale and purchase process ensures regulatory compliance, alongside having expertise in customs tariffs and taxes and the ability to manage them.

- Reducing the waste of money and goods while helping to enhance product efficiency.

- Maintaining trust between customers and the organization, thanks to the tangible quality in the final product the company offers to the customer.

Types of Purchases

Purchases in companies are classified into several types based on their purpose, such as Operating Purchases (supplies and raw materials), Capital Purchases (long-term assets like equipment), and Service Purchases (consulting, maintenance). Understanding this classification helps improve purchasing decisions and budget control.

| Type of Purchase | Description | Example |

| Operating Purchases | Daily items for production or resale. | Raw materials, office supplies, utilities. |

| Capital Purchases | Long-term assets that generate value. | Machinery, IT infrastructure, vehicles. |

| Service Purchases | Non-material contracts and services. | Legal consultation, software subscriptions. |

Goals of Purchasing Management

The objectives of Purchasing Management include the following:

- Identifying multiple sources for purchasing goods to easily find alternatives when needed.

- Supplying high-quality goods to the company without wasting money on non-essential items.

- Saving funds and planning to overcome the results of economic crises.

- Enhancing trust and friendly relations with vendors and suppliers.

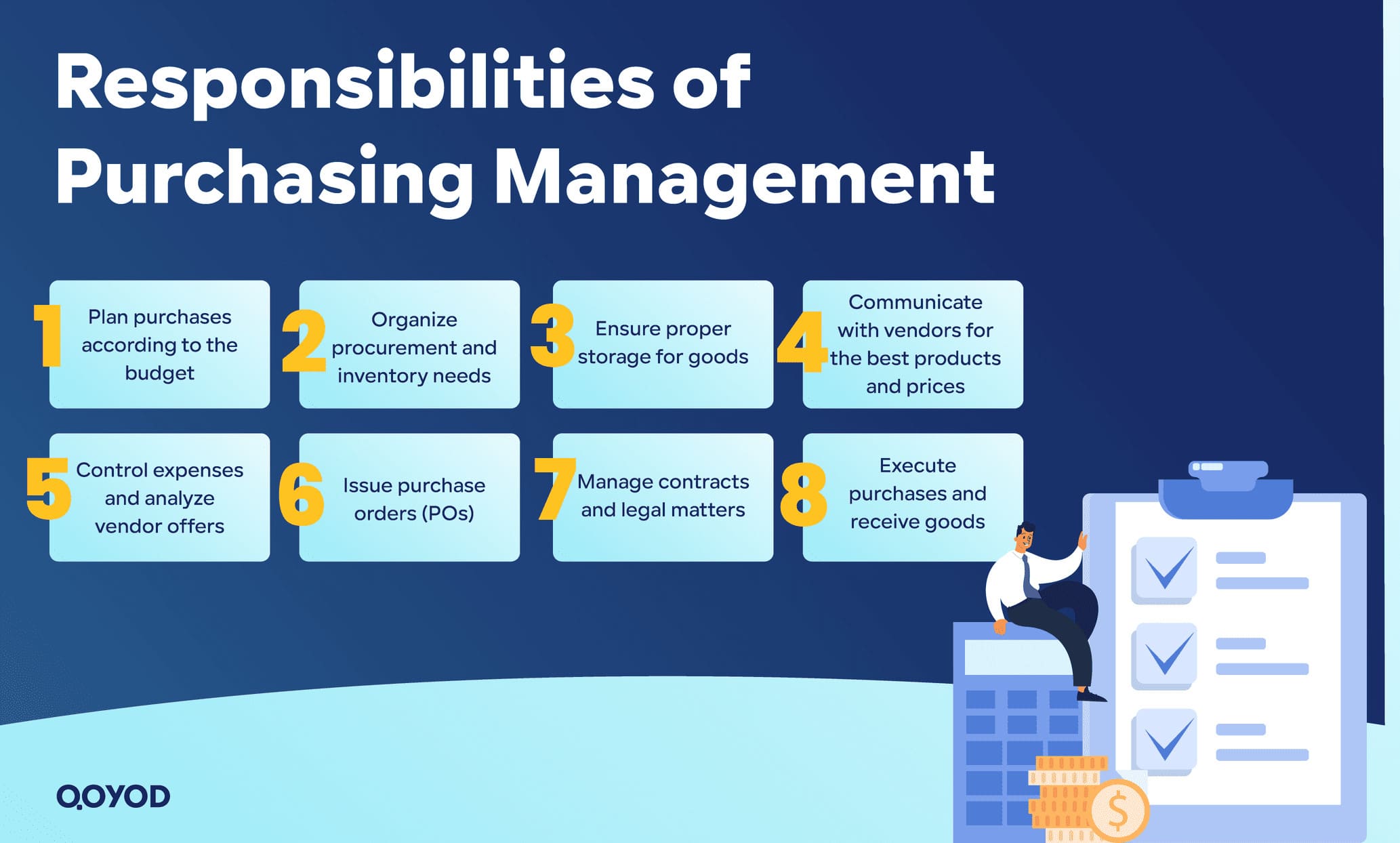

Responsibilities of Purchasing Management

Modern businesses rely on a digital purchasing management program, such as the Qoyod Accounting System, to organize procurement operations. The software helps track purchases, manage quotes, and prepare accurate financial reports that contribute to improved performance and informed decision-making.

- Setting purchasing plans that align with the allocated budget.

- Organizing the purchasing process and determining how much inventory the company needs.

- Ensuring the suitability of storage facilities for the goods that must be kept there.

- Communicating with vendors to obtain the best product for the right price.

- Controlling purchasing expenses and studying offers presented by vendors to reach the most profitable deal.

- Issuing purchase orders (POs), detailing the required goods.

- Dealing with contracts and agreements and integrating them to settle any legal matters related to the purchase.

- Executing the purchase from vendors and transferring the goods to the company’s warehouses.

Core Elements of a Purchasing Management System

A purchasing management software assists in organizing and executing purchasing operations smoothly, enabling you to track the company’s growth and determine the best time to develop the purchasing department. Below are 8 key elements that make this software an indispensable tool:

- Automated Purchase Order (PO) Creation.

- Supplier Management and Performance Tracking.

- Invoice Registration and Payment Processing.

- Real-time Inventory Tracking and Reorder Alerts.

- Comparison of Vendor Quotes and Bids.

- Financial Reporting on Spending and Cost Savings.

- Three-Way Matching for audit compliance (PO, Receipt, Invoice).

- Integration with a core Cloud Accounting System.

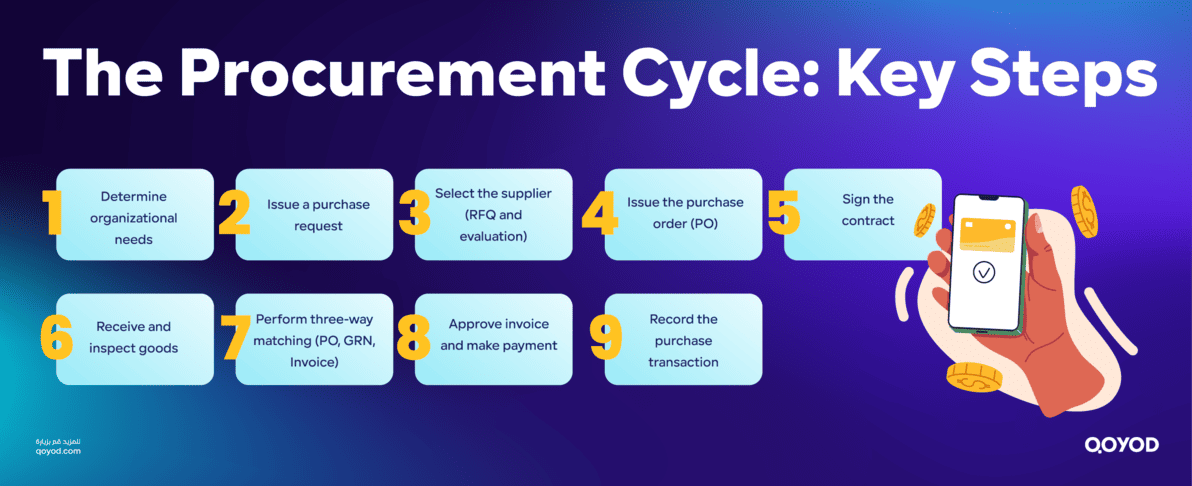

The Procurement Cycle: Steps in the Purchasing Process

The purchasing process within organizations goes through several stages, starting from identifying needs, through issuing purchase orders and comparing offers, all the way to receiving and inspecting the goods. Following these steps ensures process accuracy and minimizes financial waste.

1. Determine Organizational Needs

Identify the goods needed to keep the production process running efficiently. This must be defined over a specific period to calculate the required quantities of each item, guaranteeing sufficiency for that duration. During this time, collaboration with other departments is necessary to ascertain their requirements and ensure their provision.

2. Issue the Purchase Request

This is a formal document submitted by the relevant department to the Purchasing Management team, informing them of the details of the required goods, such as prices, type, quantities, and other information. The request may be accepted and processed or rejected and subject to modifications until it becomes acceptable.

3. Select the Supplier

This is a very important step, as this supplier may become a permanent source of goods needed by the company. A Request for Quotation (RFQ) can be sent to potential suppliers, providing them with the required product specifications. Based on the offers they provide,in terms of cost, quality level, and time required to prepare the order,you must choose the best one to deal with.

4. Issue the Purchase Order (PO)

This is a formal document detailing all specifications of the required goods. Through this, the date and place of delivery are agreed upon, as well as other details related to the requested product.

5. Contract Signing

This stage follows the presentation of the order details to the supplier, who provides their prices and the timelines for producing and preparing the goods for delivery. An agreement is reached between both parties on all aspects related to the purchase process, whether concerning delivery dates, quantity, or price.

6. Goods Receipt and Inspection

Here, you verify whether the received goods are indeed up to the required standard and quality. You also check the quantities and confirm that the received goods match what was requested in the purchase order.

7. Perform Three-Way Matching

This refers to comparing the Purchase Order (PO), the Goods Receipt Note (GRN), and the Supplier Invoice. This is done to verify the correspondence between the purchase order and the cost of the goods. Note that no costs can be paid without a clear or approved invoice.

Learn More: IFRS Accounting Standards on Inventory

8. Invoice Approval and Payment

After reviewing the details of the purchase order and the invoices and ensuring that everything is correct, the agreed-upon amount for the purchase of the required goods is paid. If the payment is deferred, the details of the settlement are agreed upon.

9. Record the Purchase Transaction

Every detail of the purchase process must be recorded accounting-wise in the cloud accounting system. This helps in evaluating the company’s trends, comparing product prices between suppliers, and provides the organization with a clear understanding of all spending channels, aiding in appropriate decision-making.

Challenges Facing Purchasing Management

Despite its importance, Purchasing Management faces several challenges, such as price volatility, budget constraints, lack of supplier transparency, and poor knowledge of tax and customs laws. Therefore, it is essential to adopt digital systems that help overcome these challenges and enhance efficiency.

- Price Increases and Volatility: This issue is faced by most companies, especially when purchasing in a different currency from the local one, as currency differences can increase costs, eliminating opportunities to reduce expenses and raise profit margins.

- Budget Limitations and Management Reluctance: A specific amount is allocated for purchasing needs based on the organization’s financial planning. This amount may not be sufficient to buy enough goods for the planned period, leading to a reduction in quantity or acceptance of lower quality, both of which negatively impact the company.

- Vendor Concentration or Saturation: Limited options can be puzzling when trying to buy goods, especially if you can’t find what satisfies your expectations. Conversely, an abundance of suppliers can cause confusion and concern about the credibility of the advantages these vendors claim.

- Lack of Supplier Credibility: This is one of the biggest challenges. A supplier may promise to produce a product with specific specifications for a set price, only for you to receive something different. This can lead to wasted money or lower product quality if the deal is accepted, and even if rejected, your company loses time and trust in the vendor.

- Incomplete Product Data: If there is insufficient information available to the Purchasing Management staff, problems will arise. The effort spent to complete the purchase will be wasted, and the product may not be up to standard, losing time and money.

- Lack of Knowledge of Procurement Laws: Lack of experience with these laws can cause customs or tax issues, or even make commercial dealings difficult. Consequently, the team may miss many opportunities due to a lack of experience in environmental and tax regulations.

How to prepare an estimated budget with practical examples? Learn More

Improving Purchasing Management Performance

To improve the performance of the purchasing department, it is recommended to implement a performance monitoring system and regularly evaluate processes, invest in employee training, and analyze past purchasing results to learn from experiences. This helps achieve best purchasing practices and avoid recurring mistakes.

- Review Past Events: Look at previous purchasing experiences the company has undergone to avoid repeating mistakes and capitalize on strengths.

- Continuous Monitoring: Constantly monitor the department’s activities to track negatives and positives and address any weaknesses that appear during performance monitoring.

- Continuous Development: Maintain the ongoing development of the procurement officer through training courses that enhance their skills and expertise, making it easier for them to keep up with new developments.

- Analyze Deviations: Monitor deviations in results and seek to understand their causes to correct them and steer clear of any potential new problems.

Purchasing Management Performance Metrics (KPIs)

Key Performance Indicators (KPIs) help measure the efficiency of Purchasing Management in financial and operational aspects. These indicators include: cost savings rate, delivery accuracy, goods quality, and contract compliance rate. By analyzing this data, performance can be improved, and more accurate strategic decisions can be made.

Cost-Saving KPIs (Financial Performance)

These metrics focus on measuring the revenues and expenses incurred by the department and help formulate better purchasing plans if expenses are high. This is achieved by measuring the following:

- Spend Ratio (Total spending vs. budget).

- Purchase ROI (Return on Investment) achieved by the team.

- Level of competition among suppliers and its impact on product quality.

- The cost of paper purchase invoices versus reliance on electronic invoicing.

Delivery KPIs (Operational Performance)

These are concerned with monitoring purchase timelines to help organize a procurement plan that aligns with scheduled delivery dates and costs. This is measured by:

- Determining the agreed-upon period from issuing the Purchase Order to the vendor until the vendor delivers the goods to the company (Lead Time).

- Knowing the availability of different vendors for the same goods to ensure the company’s needs are met when required.

- Knowing the percentage of times the company is forced to make emergency purchases.

- Determining the frequency of purchasing, or more precisely, knowing how long the purchased goods will last until the next purchasing cycle (Inventory Turnover).

Quality KPIs (Product Integrity)

Companies need high-quality goods and cannot compromise on this to avoid risking their reputation and customer trust. Therefore, the following considerations are taken into account:

- Comparing Purchase Orders to the goods actually received.

- Measuring the degree of adherence to the company’s methodology and purchasing policies, as this affects costs and profits.

- Monitoring the quality of goods and comparing it to the services offered by the supplier to determine their reliability.

FAQ: Purchasing Management and Qoyod

Here are 10 common questions with concise answers about Purchasing Management, optimized for Qoyod:

What is Purchasing Management in companies?

Purchasing Management is the process responsible for securing the company’s needs for materials and services at the best quality and lowest cost. Its tasks include planning, purchasing, negotiating with suppliers, and monitoring inventory to achieve operational efficiency and support the financial strategy.

Why is Purchasing Management important for any organization?

It ensures the continuity of the production process without interruption, helps reduce costs, improves product quality, strengthens relationships with suppliers, and reduces the risk of material shortages or sudden price increases.

What are the main goals of Purchasing Management?

Its goals are to accurately meet the organization's needs, save money by comparing offers, ensure high quality of materials, diversify sourcing channels to avoid risks, and build long-term partnerships with reliable suppliers.

What is the difference between Purchasing and Purchasing Management?

Purchasing is the execution of a payment transaction to obtain a good or service. Purchasing Management is a comprehensive approach that includes planning, supplier selection, negotiation, and post-purchase operation management to ensure maximum financial and operational efficiency.

What challenges does Purchasing Management typically face?

Key challenges include rising prices, budget constraints, lack of transparency among some suppliers, unavailability of accurate product data, or limited knowledge of customs and tax laws that affect purchasing decisions.

How do KPIs help evaluate the purchasing department?

KPIs help measure the department’s performance level in terms of delivery accuracy, goods quality, cost savings, and contract compliance level. These indicators are used to analyze results and make decisions to improve efficiency and quality in the future.

What is the relationship between Purchasing and Inventory Management?

The relationship is complementary; successful purchasing depends on efficient inventory management. The function monitors inventory levels to replenish stock before depletion, preventing production halts or the accumulation of excess goods, which represents a financial burden.

How can the performance of the purchasing department be improved within the organization?

Through training employees and developing their negotiation skills, using digital systems to monitor operations, reviewing past purchase results to draw lessons, and analyzing market data to anticipate future prices.

What is the role of the Qoyod Accounting System in Purchasing Management?

The Qoyod system facilitates the complete purchasing cycle by recording invoices electronically, issuing purchase orders, comparing quotes, tracking inventory, and providing accurate financial reports to support decision-making and improve efficiency.

How can businesses benefit from the Qoyod free trial?

By registering for the 14-day free trial, businesses can test Qoyod's tools for managing purchases, inventory, and invoices electronically, allowing them to evaluate the system and discover its ability to enhance financial and operational performance.

How to Benefit from Qoyod Accounting Software in Purchasing Management?

The Qoyod Cloud Accounting System offers integrated solutions for Purchasing Management from anywhere and at any time, with the ability to record invoices electronically, issue purchase orders, track inventory, and analyze financial data to enhance performance and improve operational efficiency.

- Varied Systems and Packages: Providing diverse systems and packages that give you what you need, from recording invoices to issuing purchase orders. These transactions remain stored electronically and can be accessed when needed.

- Supplier Database: You can implement a data network on the system to compare suppliers and determine their ability to execute the agreed-upon product specifications and quality. You also ultimately obtain documents containing complete data about these vendors for future use.

- Real-time Inventory Tracking: The Qoyod system helps you track your inventory by recording details of available goods and periodically updating them for usage. This relieves you of the problem of not renewing inventory in time and prevents stockouts.

- Comprehensive Financial Reporting: On the Qoyod accounting system, you can record all your financial transactions, meaning you receive comprehensive and complete financial reports. This allows you to evaluate the purchasing department and gauge its ability to fulfill its responsibilities, making business development smoother.

In Conclusion

Effective Purchasing Management is essential for Small and Medium-Sized Businesses to control costs and ensure high-quality operations. Digitizing this function with a reliable cloud accounting system is the path to achieving global best practices.

Try Qoyod Accounting Software now to make your business operations easier and more accurate with solutions designed for modern businesses.